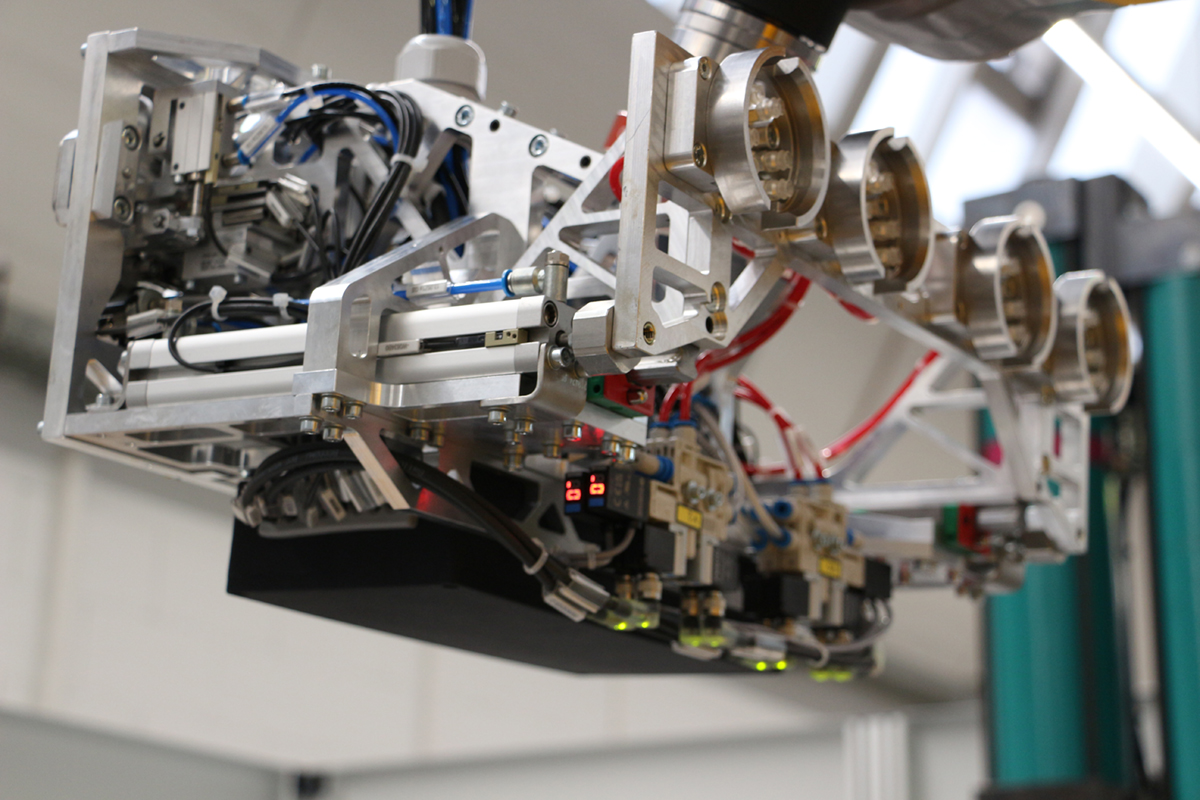

Injection molding automation for complex components

Performance and precision in plastics production

Automated removal

Reliable sorting, assembly or packaging of the injection-molded components

Parts handling and further processing

Takes over the sorting, assembly or packaging of the injection-molded components

Quality control in the process

Enables direct testing and monitoring of components after injection molding

Automated solutions for injection molding increase productivity, quality and efficiency

Automated systems in injection moulding offer decisive advantages: they speed up production, minimize sources of error and ensure consistently high product quality. M.A.i integrates state-of-the-art robotics, intelligent parts handling and inline inspection into complete turnkey solutions so that production processes can be optimally controlled and flexibly adapted to changing requirements. With the individually designed systems from M.A.i, companies benefit from consistent process reliability, high efficiency and maximum performance – from removal to quality control and packaging.

Economical and flexible production through injection molding automation

With injection molding automation, processes become more efficient, product quality increases and production remains economical and flexible even with high quantities.