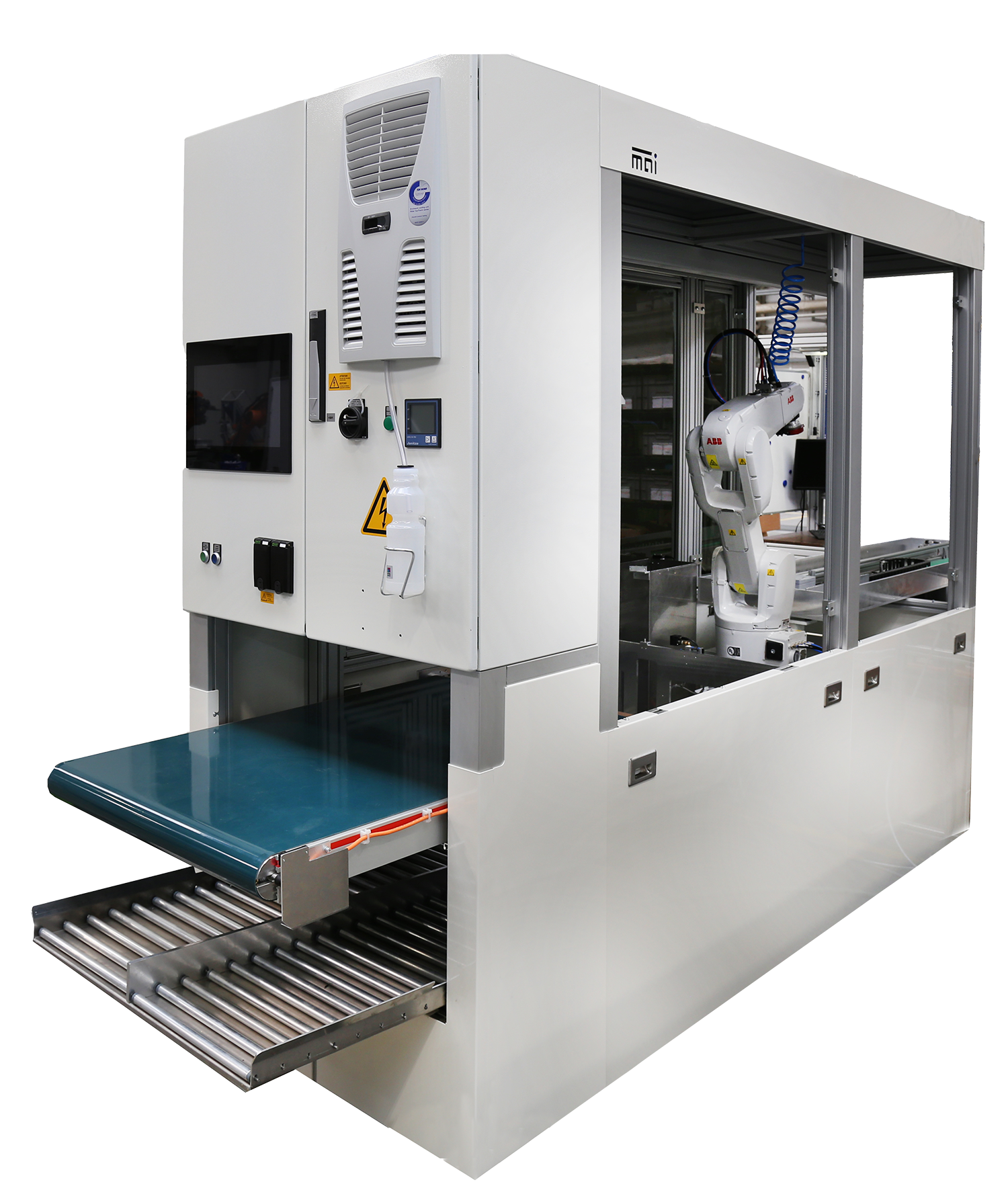

Fully automated testing and packaging cell

Robot Control & Pack cell – Innovative automation for error-free end-of-line processes.

High

efficiency

Reduces your unit costs through automated processes

Zero-defect strategy

Ensures 100% tested quality with camera test

Flexible integration

Adapts easily to different containers and processes

Efficient automation for error-free testing and packaging

The M.A.i Robot Control & Pack Cell is a state-of-the-art, universal inspection and packing cell that has been specially developed to reduce your unit costs and implement a zero-defect strategy in production. The system combines efficient, fully automated camera inspection with automatic packaging of inspected parts in suitable containers such as trays or KLTs.