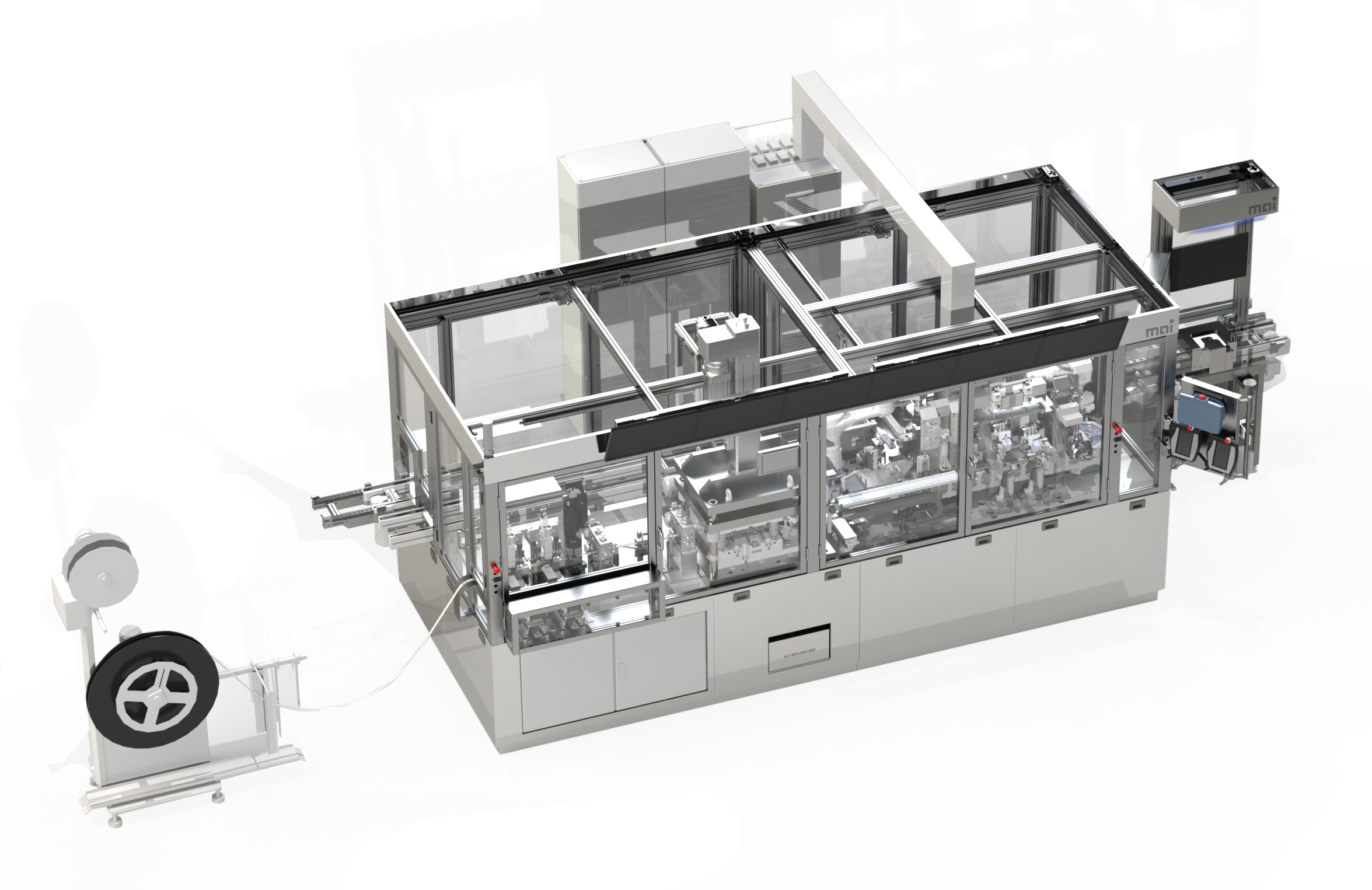

Special applications in automation

Innovative automation solutions for special requirements

Comprehensive process integration as required

In the field of mechanical engineering and automation, tailor-made solutions for special applications are crucial in order to meet complex requirements efficiently and precisely. Innovative technologies and customer-specific adaptations enable companies to optimize their production processes and gain a competitive edge.

We support you every step of the way, from consulting and design to commissioning. Our expertise in special machine construction enables us to develop individual solutions that are precisely tailored to your needs. Contact us to take your processes to the next level!

Technologies and advantages